With complete machining, welding, tube bending, and fabrication services, we create custom parts to exact specifications.

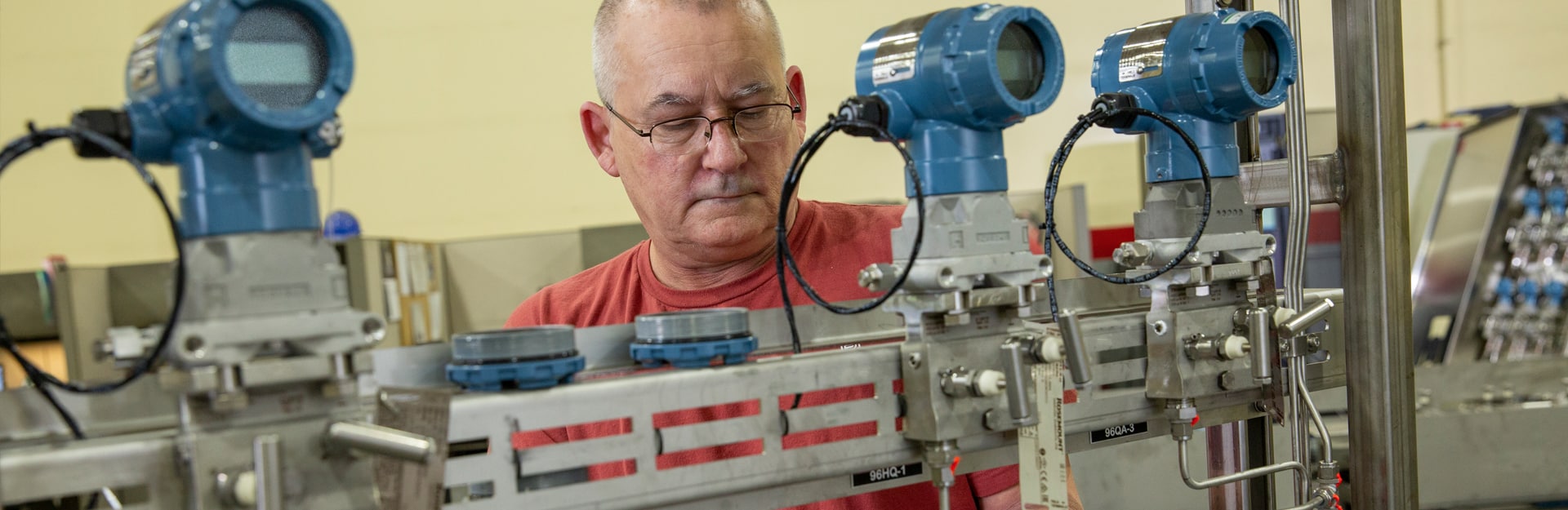

Our electromechanical assembly services include instrumentation and controls, valve assemblies, sensor devices, fuel systems components, electrical junction boxes, energy storage devices, electromechanical devices, and complex assemblies.

With a fully integrated ERP system, we make inventory management easy. We can upload directly to your BOM system and conduct bar code scanning with revision-level control, lot and serial traceability, multiple site support, and customized containers for safe onsite storage.

The Broadwind team brings extensive experience and deep expertise to the assembly and kitting of parts and complete process skids for natural gas turbines.

We simplify even the most complex solar installation project into a single transaction—and we’ll prepare, test, and package everything to match your exact workflow.

Eliminate the need for cutting, stripping, terminating, and labeling wires on the jobsite with cable harnesses coiled and crated for point-of-use simplicity.

Assembled and pre-wired for turnkey use, our racking and assemblies are built and labeled for your individual project specifications in a controlled manufacturing environment.

Our exclusive turnkey design works with multiple attachment methods (Dura-Blok, S5 clamps or ballasted) and can be customized to rack 1-4 inventers.

You make big projects happen. And you need even the smallest details covered. Broadwind Industrial Solutions takes care of it all, with high-quality assembly and precise kitting, customized to your team’s specific workflow.

You make big projects happen. And you need even the smallest details covered. Broadwind Industrial Solutions takes care of it all, with high-quality assembly and precise kitting, customized to your team’s specific workflow.  You make big projects happen. And you need even the smallest details covered. Broadwind Industrial Solutions takes care of it all, with high-quality assembly and precise kitting, customized to your team’s specific workflow.

You make big projects happen. And you need even the smallest details covered. Broadwind Industrial Solutions takes care of it all, with high-quality assembly and precise kitting, customized to your team’s specific workflow.